|

McHale Rakes: Rake Hay the Right Way For farmers, hay season is a crucial time. Getting the most out of your harvest requires reliable equipment, and that's where McHale rakes come in. McHale is a leading manufacturer of agricultural machinery, and their rakes are known for their efficiency, durability, and gentle crop handling. Building on their comprehensive range of grass machinery, McHale now introduce their R 62-72 centre delivery rake. McHale R 62-72 & McHale R 68-78 The McHale R 62-72 & 68-78 can be used to combine multiple mower rows or to row up grass, which is left on the flat. McHale centre delivery rakes are powerful but gentle on the crop, delivering the perfect swath preparation. The rotors on the McHale centre delivery rakes are suspended centrally and both rotors operate at equal ground pressure across the adjustable working width to deliver the perfect swath. McHale Rakes: Built to Last McHale offers a range of center delivery rakes, These rakes are designed to handle even the toughest conditions. McHale boasts that their rakes are tested "in the world's most difficult conditions," meaning they can handle whatever your farm throws at them. Here are some of the key features of McHale rakes:

This one-stop shop approach can simplify your equipment purchasing and streamline your haying operation. Via Jaylor.com. Dr.Alan Vaage Let’s explore the benefits of vertical TMR (Total Mixed Ration) mixers for feeding beef cows during different stages of the production cycle. Due to the high cost of forage, and feed production in general, as well as ever decreasing profit margins, cow-calf producers are increasingly recognizing the benefits of owning a TMR mixer, especially a “vertical” TMR mixer that is capable of processing baled forages to decrease feed waste and increase animal performance. Forage selection meets requirements, but creates waste: Beef cattle have a limited capacity to consume forage fiber to meet their nutritional requirements, and thus have an instinctive drive to compete for the most palatable and nutrient rich feed available. This selection behavior also acts to ensure the nutritional composition of the consumed feed is sufficient to meet requirements when the average composition of the feed is insufficient, as is often the case when “beef quality” hay is fed. Fortunately, most baled forage contains a mix of plants with a range of maturity and nutritional value. Furthermore, among the plants, leaves tend to have higher nutritional value than the stems; this is especially true for alfalfa (Table). By avoiding the coarser, lower quality material (older plants and stems) and concentrating on consuming younger and leafy material, individual animals “re-balance” the feed offered into a diet that meets, or even exceeds, their immediate nutritional requirements. The lower quality material is left behind as waste. Meeting needs with a TMR mixer: Moving from free-choice forage feeding to TMR feeding transfers the responsibility for “balancing the ration” from the cow to the producer, as the goal of using a TMR mixer is to minimize the ability of the animal to select or sort the feed ingredients. Thus, for optimal TMR feeding it is important for all ingredients, and especially from different fields and cuttings, to be analyzed for nutritional composition. In many areas feed company representatives or extension agents are happy to assist with this step, which is recommended even if feeding baled forages free-choice. Once the forages have been analyzed, bales that are nutritionally the most appropriate for feeding to a group of animals at any given stage of production can be selected and combined to make a mix that meets the requirements of the animals. With a vertical mixer, they are then processed down to a particle size that will minimize sorting and selection and fed out in a way that will ideally permit all animals to eat at the same time, with a minimum of ground loss (e.g. simple stationary or moveable feeders). In this way one can expect almost complete consumption of the bales that are fed. To improve efficiency further, one can formulate a mix at about 110% of requirements and then restrict feeding to 90% of the normal intake. As long as the cows can all eat at the same time, rate of eating will be increased and the potential for waste essentially eliminated due to competition, even with ground feeding. If the quality of the forage is less than required, cost-effective energy and/or protein supplements can be added to meet requirements and make efficient use of the poorer quality forages. If forage quality is greater than needed, it can be diluted with poorer quality forage such as straw, or limit fed according to requirements, to minimize cost and prevent waste. This demonstrates one of the greatest benefits of a TMR mixer, its scale system, which enables accurate weighing and batching of ingredients, and delivery of feed according to nutritional requirement. It provides the first requirement for improving nutritional and economic performance, for as it’s often said “if you don’t measure it, you can’t manage it”. In summary, a vertical TMR mixer can virtually eliminate the costly waste and performance limitations of feeding forage as bales, potentially reducing forage needs by up to 50%. Though this may seem high, it is the number most often quoted by Jaylor customers that switch to using a TMR mixer for feeding beef cows. TMR feeding creates a more uniform nutritional intake across the herd, and in doing so can be expected to increase both health and performance of the cow-calf herd … Because Nutrition Matters. Unless sufficient forage is provided, more of the coarse material will be consumed, at the expense of meeting nutritional requirements, and reproductive and growth performance suffer. Assuming nutritional requirements are to be met, it will take an increasing amount of waste to meet requirements as forage quality declines, up to one-third when feeding full bloom alfalfa (Table). Levels of waste with grass hays can be even greater because of a smaller difference in quality between leaves and stems in grasses versus alfalfa. When forage selection losses are combined with palatability losses due to weathering and mold, as well as ground losses due to feeding method, it is easy to see how overall, nutritional waste from bale feeding easily ranges from 30 to 50 percent. Further losses occur due to variable intake between animals which reduces aggregate reproductive and growth performance; this will be discussed in a subsequent article. Table: Alfalfa composition by stage of maturity, and feeding rate required to permit animals to equalize intake TDN composition by selecting against consuming stems. Already thinking of Spring '23? We have new McHale mowers to consider! To achieve the maximum performance and results from a front and a rear or combination mower the cutter bar and mower suspension works together to deliver uncontaminated forage. As a result McHale have developed unique patented ground adaption technology which deliver 3 dimensional ground contour tracking for its Pro Glide range of rear and combination mowers which allows an arc of movement from left to right and forward and back movement adjusting to changes in the contours of the ground. The Pro Glide range of rear and combination mowers is fitted with patented ground adaption technology which allows the bed to move back and up if the bed encounters small obstacles. This saves time and maximizes throughput as it means the obstacle does not trigger the main break back protection. This results in higher mowing speeds being able to be achieved without the interruption of having to reset the break back. If the mower hits an immovable object, it is fitted with mechanical break back which will be triggered. The Pro Glide rear suspension springs react instantly to ground contours which results in high quality cut even when working at high ground speeds. This allows the mower to easily mow on rough or undulating terrain and still deliver optimum results. On the Pro Glide rear and combination mowers the cutter bar ground pressure can be set from the tractor cab. The working pressure is visually displayed on the clock which is mounted on the headstock. Once the desired pressure is selected the cutter bar working pressure can be isolated from the tractor hydraulics with a mechanical tap. On the McHale Pro Glide range of rear and combination mowers the gearbox powering the cutter bar is located behind the first mower disc which allows the operator to mow into corners and over rough terrain with no problems occurring. For transportation, the McHale Pro Glide folds vertically to position itself behind the centre point of the tractor for safe transport. The transport height of the machine is reduced thanks to the positioning of the mower bed at 110 degree angle on the Pro Glide R3100 to measure at a height of 3.9 metres while the Pro Glide B9000 is positioned vertically in transport to measure at a height of 4.2 metres. This position allows for the center of gravity to be close to the tractor which ensures even weight distribution and stability during transport at high speeds on the road or in uneven fields. This position allows for the mower to distribute its weight across the tractor for ease of transport on the road while also providing the driver with a clear view from his rear-view mirrors. Heard about McHale Balers, Balewrappers and Hay handling equipment? We have a facebook group dedicated just to Owners of McHale products where customers can get help with parts and service questions as well as community where you can share pictures and video! Below are a few examples of our members posts as well as a link to the group if you are a McHale owner and wish to join!

Many industries, including Agriculture are experiencing issues with a labor shortage. If you are wondering how you could speed up harvest without investing in more help and more trucks, there’s something you should consider. Oxygen free grain storage, or grain bagging, can help. With grain bagging you will be able to harvest now, store grain for an extended period of time with no degradation to your grain quality. But what exactly is oxygen free storage? Lets get scientific. Inside a grain bag is your grain, and whatever quality it goes in at, is what it will come out at. How does this occur? First, aerobic bacteria that is on your grain will use up the free oxygen available in the bag. While it does this, the bacteria are expelling Carbon Dioxide, which increases C02. Because of this, there is a decrease of deterioration in your grain, as well as controlling mold and insect infestation-because bugs cannot live without oxygen. There is no decrease in grain grade due to shrink (like in a grain bin) or oxygen degradation. So essentially there is not much going on inside the grain bag except protection from the outside world, which is just what you want. Why wont I need extra labor? You wont need extra labor if you add a grain bagger in your mix because one person can run a grain bagger, and they don’t even necessarily have to be running just the bagger, the help you already have running the tractor with a grain cart can hop off and run the grain bagger while its getting dumped into. Why wont I need extra trucks or truck drivers? Grain bagging allows you to bag wherever you are harvesting, along the side of the field or your place of choice. This way, you can dump from your grain cart right near where you are harvesting. This allows you to keep your combines running, not sitting waiting on trucks which seem to be getting harder to come by. You also don’t have to drive back and forth to a bin and waste fuel.

What other benefits can I expect from bagging grain?

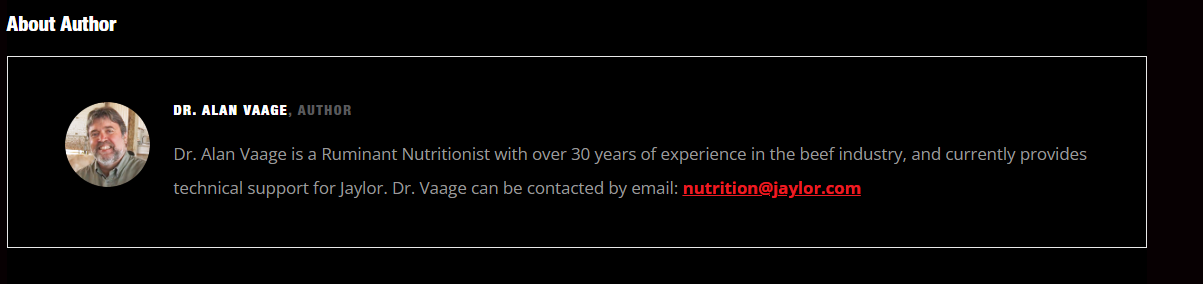

Listen to an Iowa Farmer discuss the value of bagging his grain with Richiger:

Hay season is rolling in the Midwest! We have had lots of customers send in their videos and pictures, so we wanted to share some of those with our community. (Left Image: Magsig Farms in Macedonia, Illinois running their Tubeline TL50 balewrapper. Right Image: Customer with Kuhns Equipment, Lovington, Illinois using their McHale Vario Baler/Wrapper Combination Machine. ) Video: Customer in Illinois using their W2020 Stacking Balewrapper from McHale. (Left image: Round Top Ag in Thomas, Oklahoma running 2 McHale V8 balers. Right image: Dammann Farms in Clarinda, Iowa wrapping dry hay with a Tubeline TL50 Balewrapper. ) Video: Demo in Vandalia, Missouri with hay products Teagle C12 processor, Schaffer Wheel Loader & McHale 691 Bale Handler. As the US gets more of a grip on the Covid pandemic during this summer 2021, the US is projected that building and maintaining infrastructure will be a major factor that will also increase jobs, and with that comes the need for equipment that can do multiple jobs and hold multiple functions at the job site. This got us thinking about loaders. Most of us know that we can go out and buy or rent a Wheel Loader, or a Telehandler, but there is a new loader on the market that will do both jobs: Schaffer Telescopic Wheel Loaders. What is a Wheel Loader? “A loader is a heavy equipment machine used in construction to move or load materials such as soil, rock, sand, demolition debris, etc. into or onto another type of machinery.” (Google) What is a Telehandler? A telehandler is defined as “A telescopic handler, also called a telehandler, teleporter, reach forklift, or zoom boom, is a machine widely used in agriculture and industry.” (Google) Can Schaffers really be used as both a Telehandler & a Wheel Loader? Yes! Schaffer loaders were designed for both agriculture and construction industries. Their narrow working width makes them perfect for fitting into tight barn or project site spaces, while also allowing for high lift heights and the ability to use the telescopic boom like a telehandler! This machine has replaced several machines on our customers farms and job sites- making them a respected member of their team. See one of our customers testimonials below along with some recent demos we've done with Schaffer Loaders:

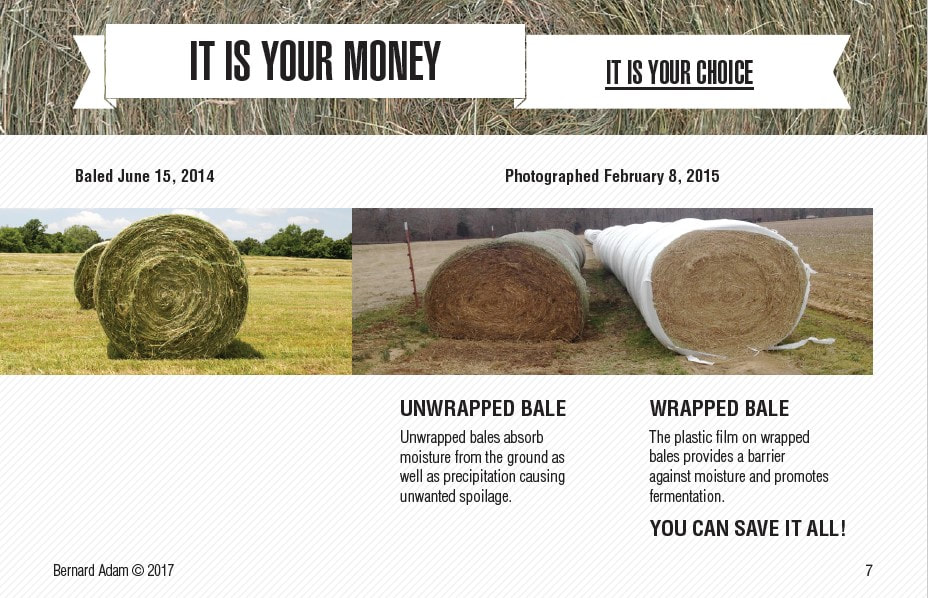

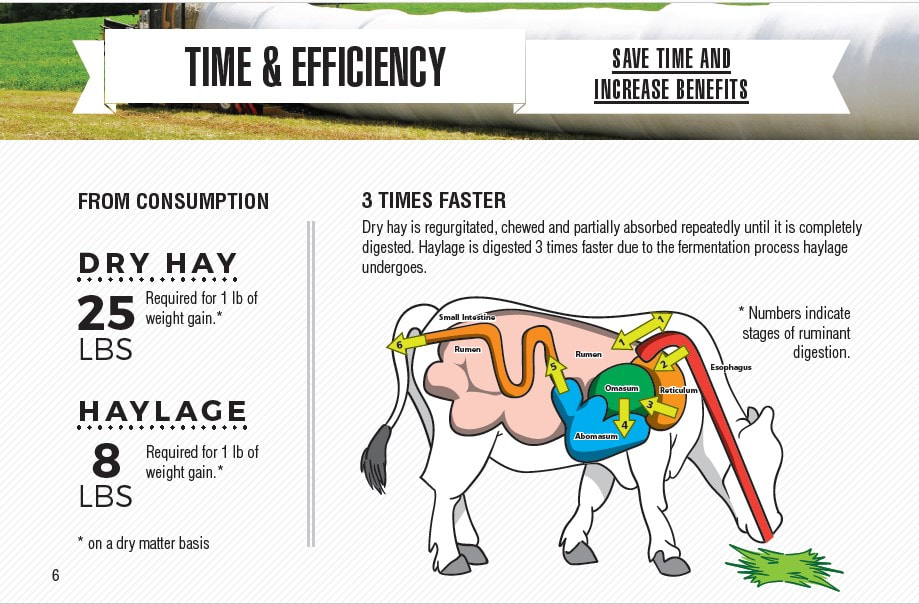

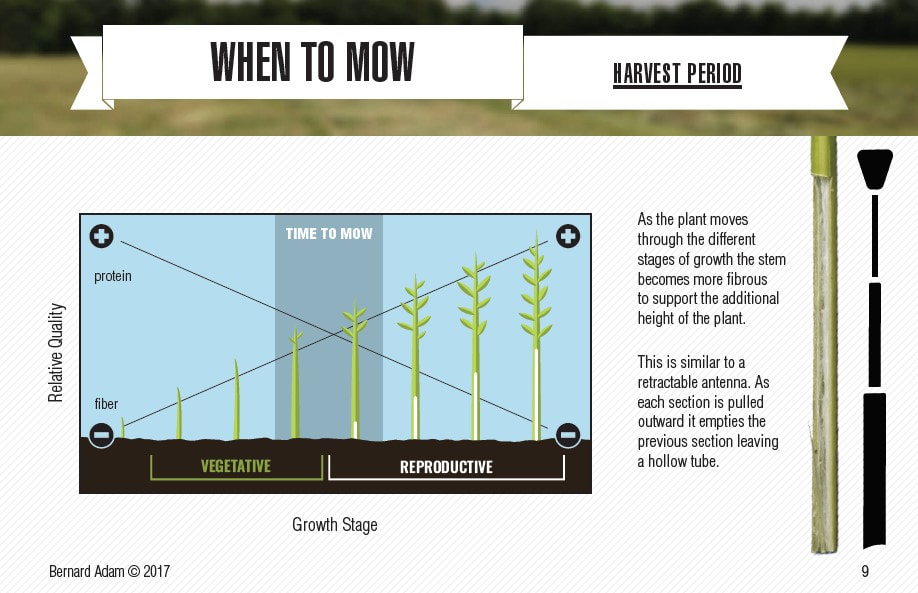

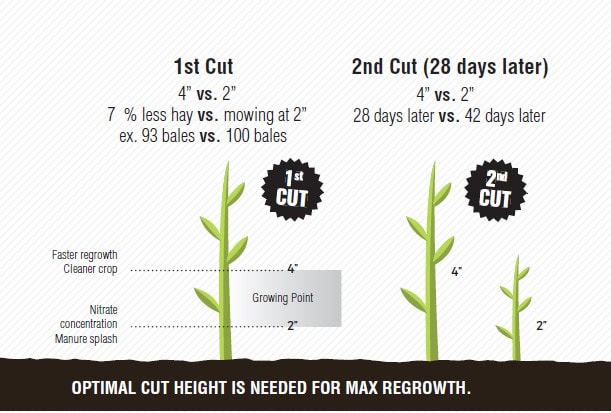

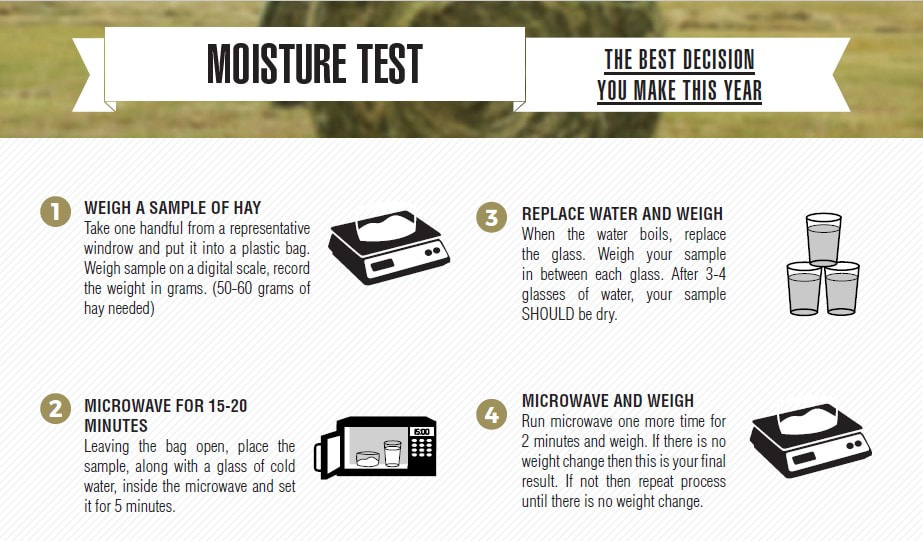

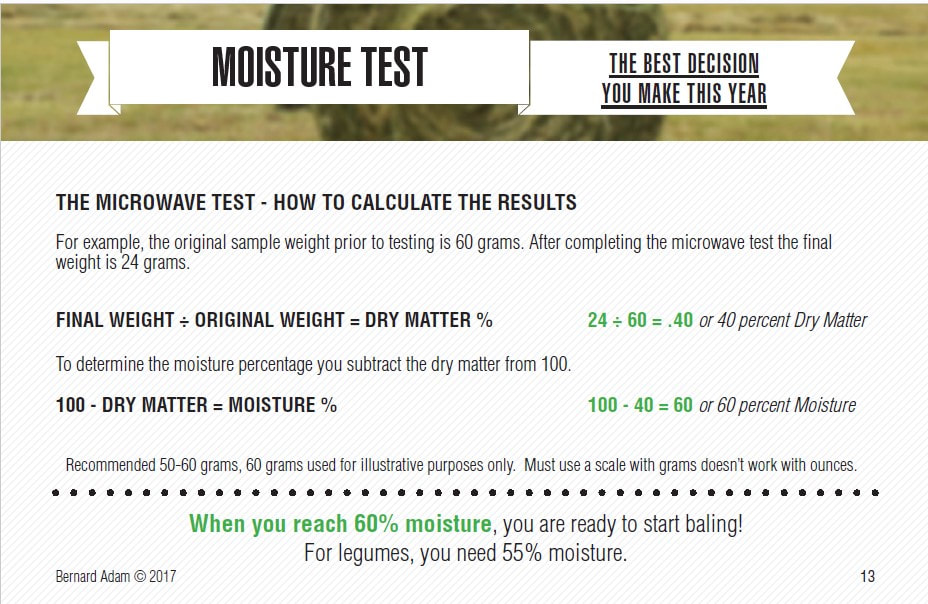

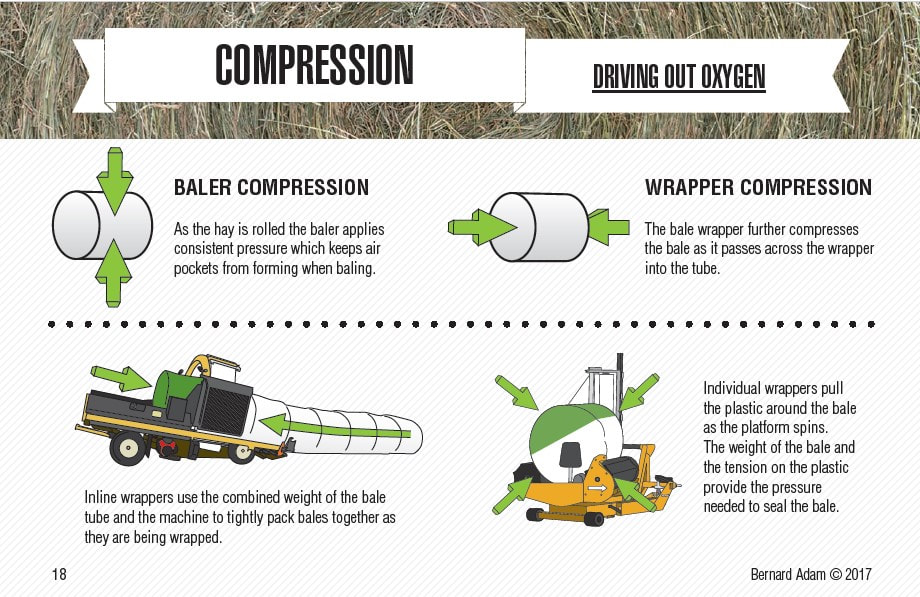

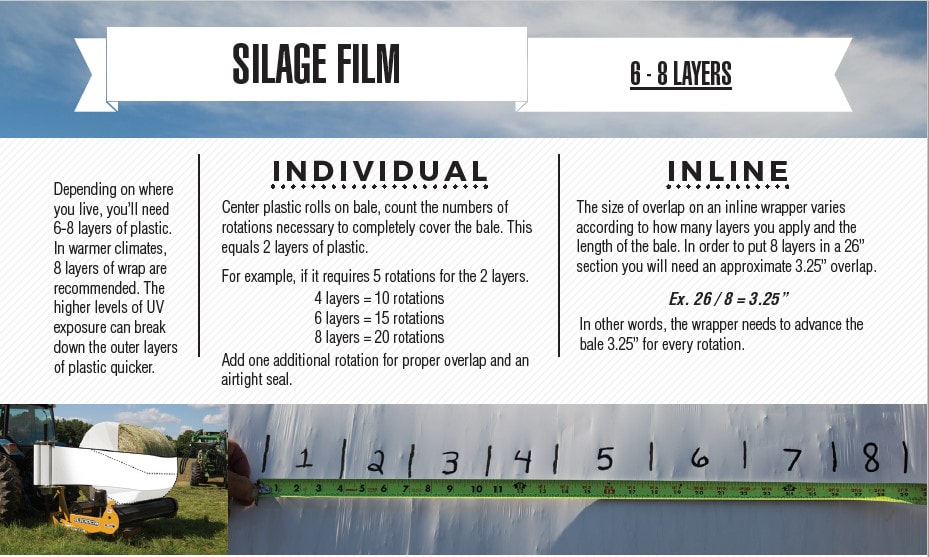

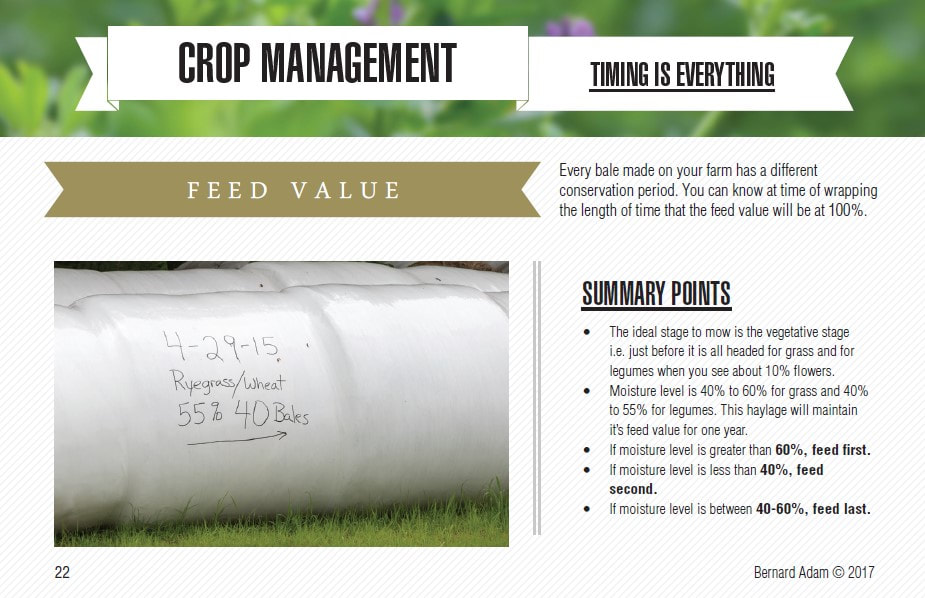

For years farmers in many states have been able to receive great interest rates for farm storage facilities on their farms through their Farm Service Agency. This program has helped around 33,000 farmers of small to medium size as well as many new farmers increase their storage capacity for storing grain and hay on their farm. They extended this program for 2019-2020, and now 2021 and we have had several customers take advantage of it. This is a great opportunity for farmers who would like to update their silage equipment this year! Here is the information directly from the USDA/FSA website regarding this matter: “The Farm Storage Facility Loan Program (FSFL) provides low-interest financing so producers can build or upgrade facilities to store commodities. Eligible commodities include grains, oilseeds, peanuts, pulse crops, hay, honey, renewable biomass commodities, fruits and vegetables, floriculture, hops, maple sap, milk, cheese, yogurt, butter, eggs, meat/poultry (unprocessed), rye and aquaculture. Eligible facility types include grain bins, hay barns, bulk tanks, and facilities for cold storage. Drying and handling and storage equipment is also eligible, including storage and handling trucks. Eligible facilities and equipment may be new or used, permanently affixed or portable. Since its inception in May 2000, more than 33,000 loans have been issued for on-farm storage, increasing storage capacity by 900 million bushels. FSFL is an excellent financing program for on-farm storage and handling for small and mid-sized farms, and for new farmers. Loan terms vary from 3 to 12 years. The maximum loan amount for storage facilities is $500,000. The maximum loan amount for storage and handling trucks is $100,000. In 2016 FSA introduced a new loan category, the microloan, for loans with an aggregate balance up to $50,000. Microloans offer a 5 percent down payment requirement, compared to a 15 percent down payment for a regular FSFL, and waive the regular three-year production history requirement.” If this sounds like a good program for you, take a peek at some of the available balers and wrappers we offer below and get a taste of which one might be right for your operation. We should note that grain baggers also fall under this storage loan program, and you can read more about the grain bagging side of it in our earlier blog: Grain Bagging: FSA Loan Can Help! In Line WrappersTubeline balewrappers have been trusted in the industry as reliable, feature loaded wrappers. The NEW TL60 Wrapper features a soft start and will wrap both round and square bales. The NEW TL50 Wrapper features a soft start and will wrap round bales. The TL5000 model will wrap round bales up to 5’6” The TL5500 model will wrap round bales up to 5’6” as well as square bales up to 3’x3’x5’6” The TL6000 model will wrap round bales up to 6' and square bales up to 3'x3'x6'. The TL6500 model will wrap round bales up to 6’, single square bales 4’x4’x6’ and 3’x3’x7’ OR double stacked square bales up to 3’x4’x6’. Tubeline also offers ECV balewrappers which build upon the proven success of the AX2 wrappers, but has digital control and easy to use presets and bale counters, custom operators love these machines. Balers.McHale V660 The McHale V660 Baler is a 15 knife chopper variable chamber round baler, you can make bales anywhere from 2ft 4 inches to 5ft 6inches. It makes bales of custom operator quality that are unsurpassed in silage quality. Read more about why your cows want chopped hay here. McHale V8950 The McHale V8950 offers the same great features of the V660 but will make round bales 2' to 6'3"! Baler/Wrapper Combination Machines.Mchale Fusion Vario The McHale Vario can make bales of haylage/silage of 3ft 3 inches to 4ft 8 inches and bales of hay and straw from 2ft to 5ft 6inches. It bales and wraps all in one machine. McHale Fusion 3+ McHale Fusion 3+ this combination machine will bale and wrap 4x4 bales The McHale Fusion 3 Plus integrated baler wrapper uses Film on Film technology to apply film to the barrel of the bale in the bale chamber. Film on Film technology has been proved to increase the feed value of your bales by replacing net wrap with another layer of special film that binds the bale together forming a wrap layer and gives you better plastic coverage on the largest surface of the bale. Single Round Balewrappers For small producers only wrapping 500 or less bales per year: Tubeline TL1000R Are you looking for an easy to use, easy to maintain single Balewrapper? Now you can wrap your hay easier, up to 5X5’6” diameter bales with the Tubeline TL1000R Balewrapper. This easy to use Balewrapper uses tractor hydraulics to spin and rotate the bale while it’s being wrapped so that each bale is wrapped completely and evenly every time. LEARN MORE. For producers needing a high output, high quality machine: McHale 991 Series balewrappers For the medium to high producer, there is a single round bale wrapper that stands out among the pack, the McHale 991 wrapper series. These are trailed units that come in either cable controlled with 4 levers (991 BC) or with fully electronic in tractor settings (991 BE). The McHale 991 single bale wrappers are self-loading, and have a high output rating for producers who need to wrap bales fast and efficiently. McHale 991 High Speed For high output producers, the 991 High Speed Bale Wrapper will increase your production with its speed! As shown in the video below, the high speed wrapper has the great features of the 991 BC/BE units, but with a 50% increase in output. These wrappers will wrap bales in approximately 30 seconds! Orbital high speed balewrapper A high speed solution which delivers consistent and even overlap and achieves optimum levels of fodder preservation and quality. The McHale Orbital Bale Wrapper is a high speed round bale wrapper. The McHale Orbital harnesses the proven vertical wrapping ring technology used in the McHale Fusion to deliver a high output, low maintenance bale wrapper which is capable of keeping up with multiple balers. Single Square BalewrappersFor small producers only wrapping 500 or less bales per year: Tubeline 1700SR The TL1700SR trailed bale wrapper will wrap BOTH Square AND Round bales! This is a trailed unit that will wrap 3’x3’ square bales from 4feet to 7 feet long and 4’x4’ & 5’x5’6” round bales- making it versatile for whatever kind of bales you need to wrap. LEARN MORE. For producers needing a high output, high quality machine: McHale 998 square balewrapper Do you need a high output square bale wrapper that can wrap 80-100 bales an hour? The McHale 998 single square bale wrapper is a feature packed single bale wrapping machine that has a conveyor that loads square bales from the field and loads them for wrapping. The McHale 998 square bale wrapper will wrap bales up to 5.9ft in length and can wrap double stacked bales. LEARN MORE Resources: https://www.fsa.usda.gov/programs-and-services/price-support/facility-loans/farm-storage/ https://www.fsa.usda.gov/Assets/USDA-FSA-Public/usdafiles/FactSheets/2017/farm_storage_facility_loans_nov2017.pdf There are six main steps to making great silage! Mow wide windrows, Moisture Test (keep reading we show an easy microwave trick to test moisture) , Rake (as needed), bale tight and uniformly, haul (no further than necessary) & Wrap within 4-8 hours after baling. We will go through each of these steps and also offer answers to some of our most asked questions about wrapping hay! What is high moisture hay and why should I wrap it? High moisture hay can be referred to as haylage, baleage, and silage. It is <60% moisture hay that has been wrapped airtight and allowed to ferment. Minimizing harvest loss, reducing harvest time, increasing average daily gain, minimizing storage loss, reducing feed cost, and reducing weather risk are reasons to produce high moisture hay. Unwrapped bales absorb moisture form the ground and precipitation causing spoilage while wrapped hay provides a plastic film barrier against moisture and promote fermentation, so you can save it all. When should I mow? You should mow during the vegetative state while at 4” because it leaves a higher concentration of nitrates and helps to boost regrowth. The growing point is saved and immediately starts growth. How should I mow? Mowing at 4” leaves a higher concentration of nitrates, helping to boost regrowth. The growing point is saved, and is able to immediately start growth. Hay mowed at 2” includes a higher concentration of nitrates, manure splash, ashes and dirt, as well as increasing the fertilizer costs associated with nutrient replacement. How can I test moisture? The graphic below shows a microwave technique you can use to test moisture. Does my baler matter when it comes to making silage? Compression drives out the oxygen. As the hay is rolled the baler applies consistent pressure which keeps air pockets from forming when baling and it further compresses the bale as it passes across the wrapper into the tube. The tighter compacted a bale is, the better silage you will produce. Balers like the McHale V6&V8 chopper balers are industry standard for compact bales perfect for wrapping. Inline wrappers use the combined weight of the bale tube and the machine to pack bales tightly together as they are wrapped. Individual wrappers pull the plastic around the bale as the platform spins. The weight of the bale and tension on the plastic provides the pressure needed to seal the bale. How many layers of plastic should I use? Depending on where you live, you will need 6-8 layers of plastic. You need the film to last at least one year outside in the sun. In warmer climates, 8 layers of wrap are recommended because higher levels of UV exposure can break down the outer layers of plastic quicker. Plastic, exposed to heat and cold, will keep expanding and contracting when using a quality film product. Film storage is critical, film should not be exposed to extreme heat or sunlight for long periods of time. This plastic should be white to reflect the heat. Any other color will ABSORB the heat instead of reflecting it. Too high a temperature inside the bale will bond the protein to the fiber and increase the time needed by cows to digest the fiber, thus reducing the space in the cows rumen for new forage intake. This is known as the “bonded protein” effect. This will result in a loss of profitability! During periods of hot weather, you must clean the pretensioner rollers frequently to remove cling deposits. This will control the stretch to levels you need (55% to 75%). Overstretched plastic, 75% or greater, may result in premature film degradation and barrier properties. The lack of oxygen barrier allows the CO2 inside the bale to escape. What type of silage film should I use? You should look for good silage film that will provide an excellent oxygen barrier that will keep the CO2 inside the bale. If you lose CO2, your haylage will develop mold. You need enough tack or cling on the film to seal the bale. When should I feed silage bales? Every bale that is made on your farm has a different conservation period. You can know at time of wrapping the length of time that the feed value will be at 100%. Moisture level is 40% to 60% for grass and 40% to 55% for legumes. This haylage will maintain it’s feed value for one year. If moisture level is greater than 60%, feed first. If moisture level is less than 40%, feed second. If moisture level is between 40-60%, feed last. In review, there are 6 main steps outlined in images below, that will give you the tools you need to make the best silage/haylage this season! Resources: The How and Why of Silage, 2017 Bernard Adam & Tubeline Mfg. See full text here. The right baler can increase the carrying capacity of your farm per acre; more efficiency equals less wasted fertilizer and lower costs of production. What is a farms carrying capacity? “Carrying capacity describes the number of grazing animals a management unit is able to support without depleting rangeland vegetation or soil resources.” (globalrangelands.org) So, how can a baler do this for your farm? Some balers, like the Mchale V6 chopper balers and now the V8 Chopper Balers, are famous for efficiency. We have now introduced the all new V8 Series of McHale balers, with all of the hay eating and processing factors of its little brother, but in a larger diameter package (6’3”) and the ability to make an even tighter bale! In what ways are McHale V8 balers more efficient than other balers? 1.They pack more hay into a bale. The more hay you have for a given size of bale the less oxygen there is and less mold will occur, it will also shed water better even if it’s not wrapped. 2.Chopping balers create less waste. Since you can determine your desired chop length,your cattle doesn’t have to work as hard to chew the hay. Long stem hay creates waste because a lot falls on the ground when cattle eat it. It also makes other processes run better like a TMR mixer because the bale is already chopped, so it takes less time to grind it with other ingredients in your TMR mixer. 3.They make your hay stay fresher longer. Tightly packed bales means cattle will want to eat it as opposed to loose bales. Looser bales have more decay which cattle don’t like. 4.They use less fuel. McHale Balers are 15 seconds faster than other balers. While 15 seconds might not seem like much, that’s a quarter of an hour, a quarter of your day that will be saved in time and fuel! Think a chopper baler might be right for you? Check out more info below! |

RSS Feed

RSS Feed